Products

-

Manual

StandardProducts >

StandardProducts > PUSH-PULLProducts >

PUSH-PULLProducts > SeparableProducts >

SeparableProducts > StandardProducts >

StandardProducts > PUSH-PULLProducts >

PUSH-PULLProducts > -

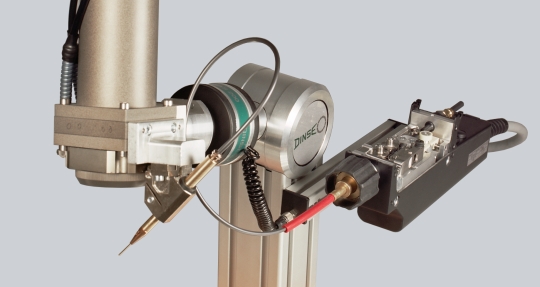

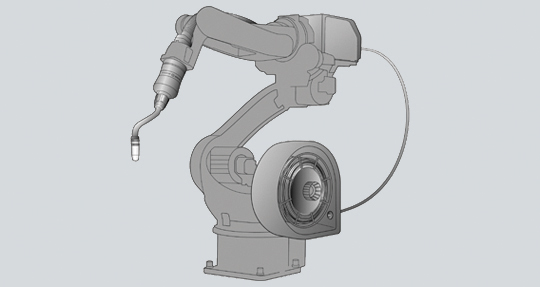

Automation

Torch headProducts >

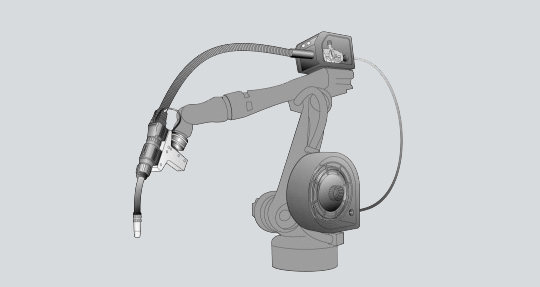

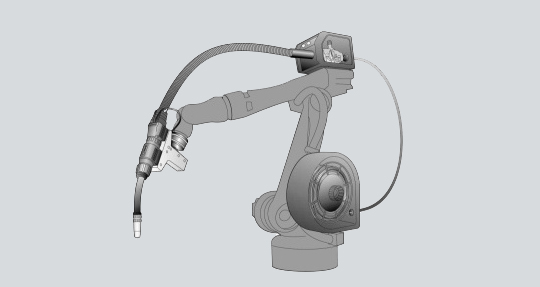

Torch headProducts > Hollow wrist robotProducts >

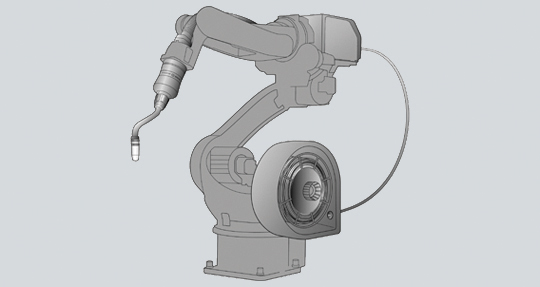

Hollow wrist robotProducts > RobotProducts >

RobotProducts > Torch headProducts >

Torch headProducts > Hollow wrist robotProducts >

Hollow wrist robotProducts > RobotProducts >

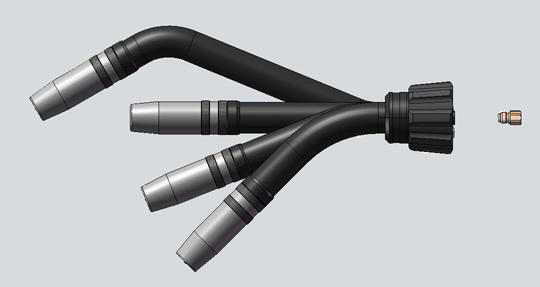

RobotProducts > SeparableProducts >

SeparableProducts > Not separableProducts >

Not separableProducts > Cold wire setsProducts >

Cold wire setsProducts > -

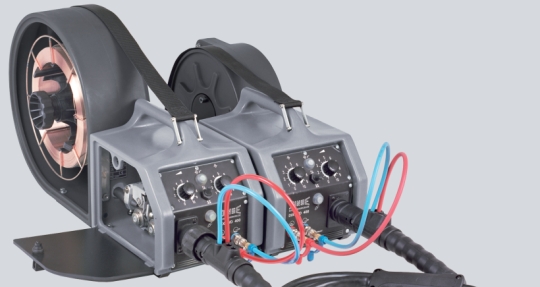

Wire Feeder

Wire feederProducts >

Wire feederProducts > ComponentsProducts >

ComponentsProducts > Wire feederProducts >

Wire feederProducts > ComponentsProducts >

ComponentsProducts > Wire feederProducts >

Wire feederProducts > ComponentsProducts >

ComponentsProducts > Wire feederProducts >

Wire feederProducts > ControlsProducts >

ControlsProducts > ComponentsProducts >

ComponentsProducts > Wire feederProducts >

Wire feederProducts > ControlsProducts >

ControlsProducts > ComponentsProducts >

ComponentsProducts > AccessoriesProducts >

AccessoriesProducts > Wire feederProducts >

Wire feederProducts > ComponentsProducts >

ComponentsProducts > Wire feederProducts >

Wire feederProducts > ControlsProducts >

ControlsProducts > ComponentsProducts >

ComponentsProducts > -

LASER

Wire feederProducts >

Wire feederProducts > ControlsProducts >

ControlsProducts > -

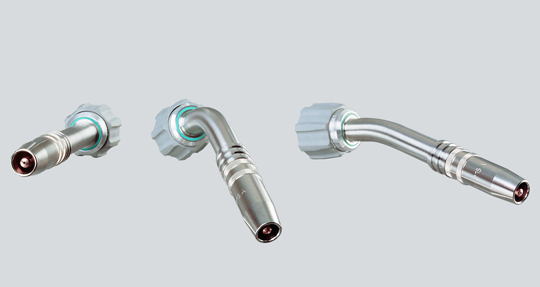

Plugs / Sockets

Cable plugsProducts >

Cable plugsProducts > Build-in plugsProducts >

Build-in plugsProducts > Cable joint plugsProducts >

Cable joint plugsProducts > Cable socketsProducts >

Cable socketsProducts > Build-in socketsProducts >

Build-in socketsProducts > Cable joint socketProducts >

Cable joint socketProducts > -

Accessories

Checking jigProducts >

Checking jigProducts > Aligning moduleProducts >

Aligning moduleProducts > Aligning setsProducts >

Aligning setsProducts > Torch cleaning station with springProducts >

Torch cleaning station with springProducts > Torch cleaning station with reamerProducts >

Torch cleaning station with reamerProducts > Pressure regulator for cylinder connectionProducts >

Pressure regulator for cylinder connectionProducts > Pressure regulator for outlet pointsProducts >

Pressure regulator for outlet pointsProducts > Capillary linerProducts >

Capillary linerProducts > Capillary linerProducts >

Capillary linerProducts >

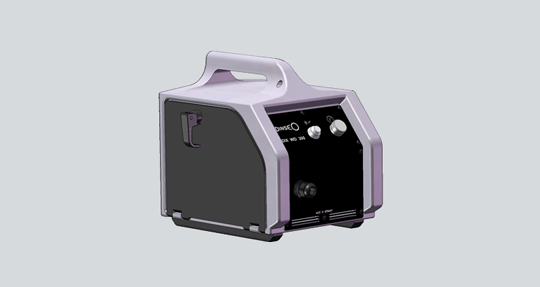

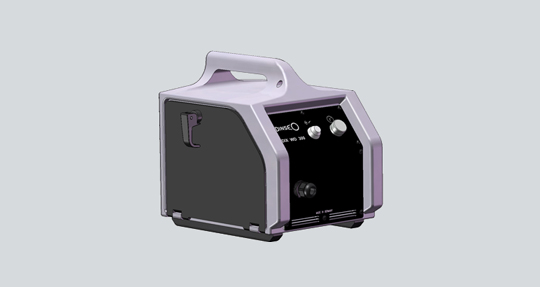

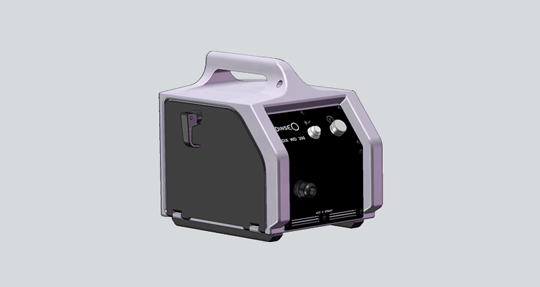

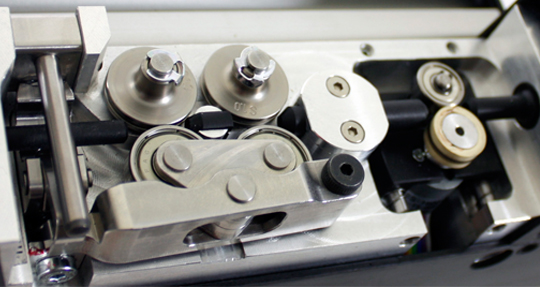

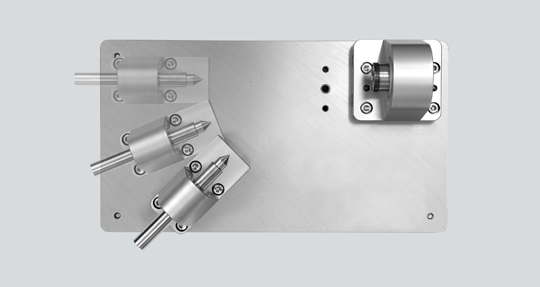

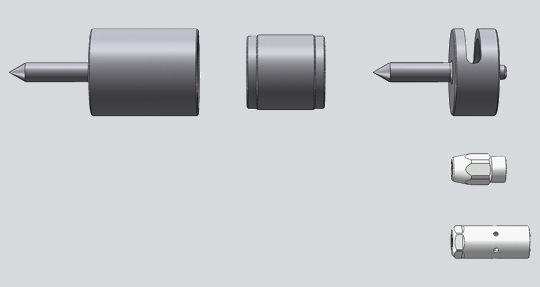

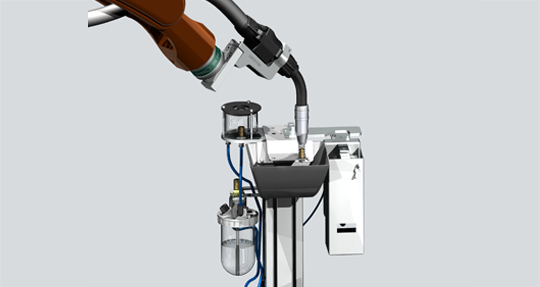

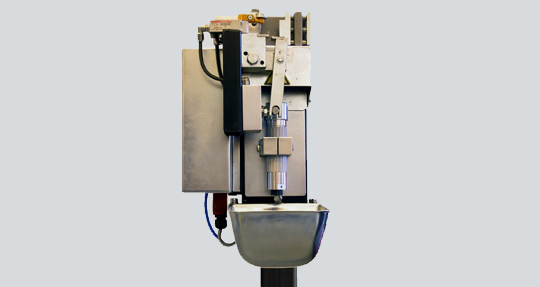

Products > Accessories > Tool storage station > WAS 100

WAS 100

Whether replacing wear parts or changing tools for a different manufacturing process – both procedures can be performed without interrupting production. The tool storage system ensures high system availability and high flexibility

Vorteile

- High flexibility and system availability thanks to quick tool change with storage station

- reproducible tool positioning through form-fitting locking mechanism on the robot

- Pneumatic locking system independent of robot

- Monitoring of tool tray via Reed contact

- self-locking in event of power failure by means of springs

Product Information

Manual