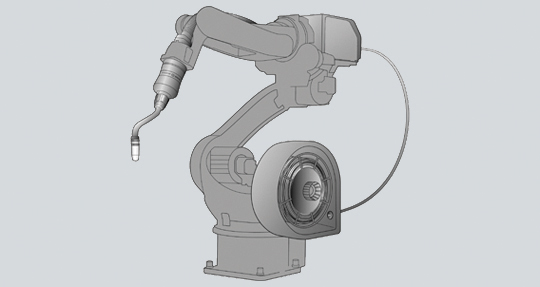

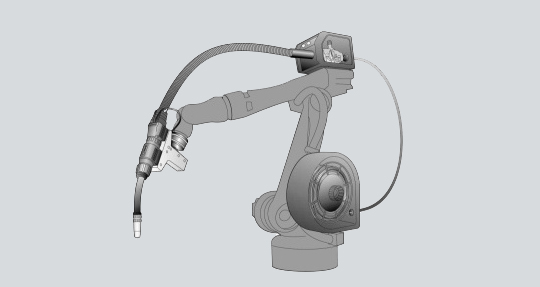

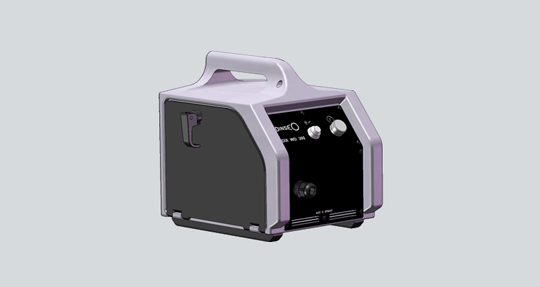

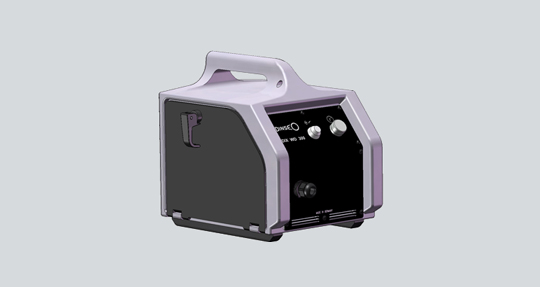

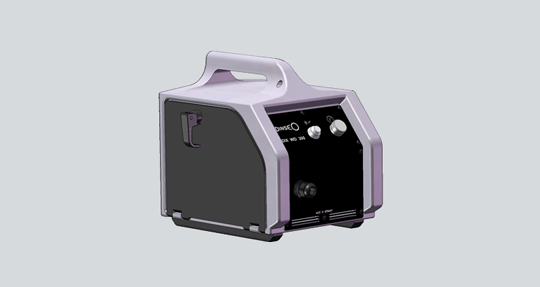

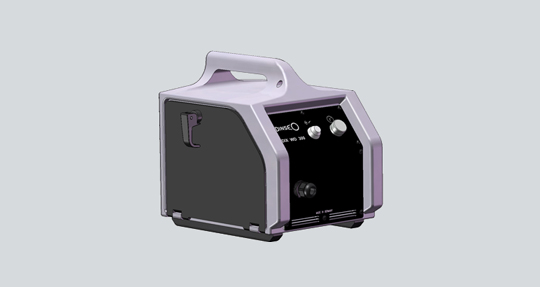

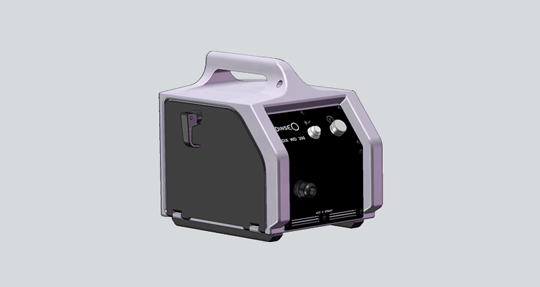

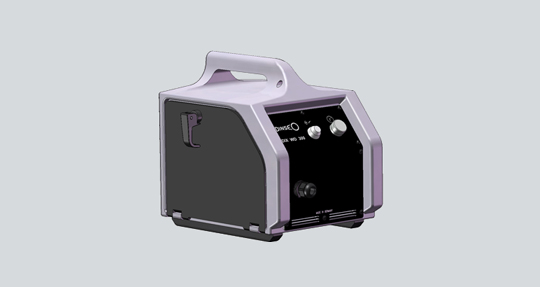

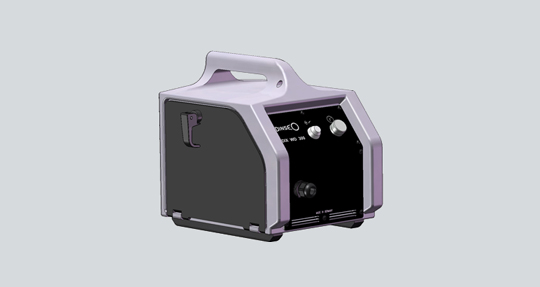

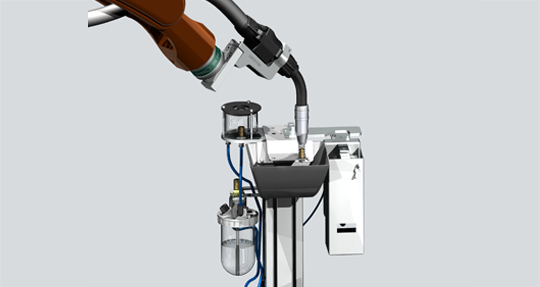

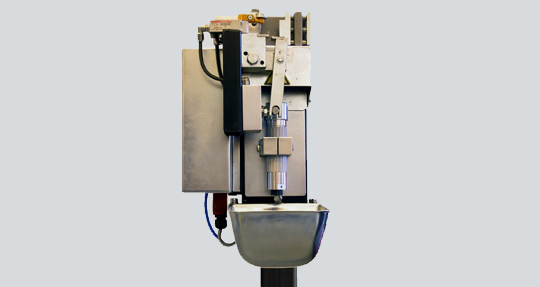

Gas-cooled torches with industry leading performance

The gas-cooled series DIX MET 32xx, DIX MET 37xx and DIX MET 39xx offer an impressive range of performance. With a duty cycle of 100%, they are designed for performance outputs up to 450A with CO2 and up to 400A with mixed gas.

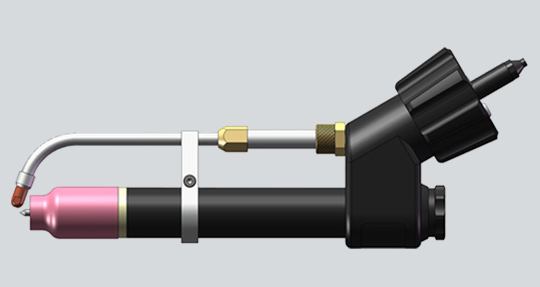

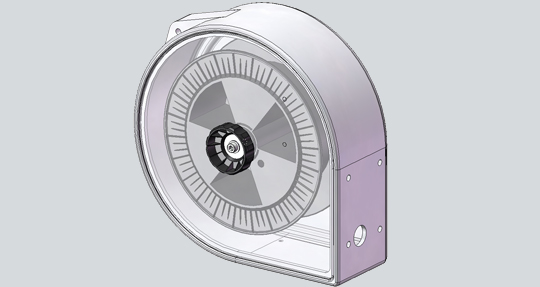

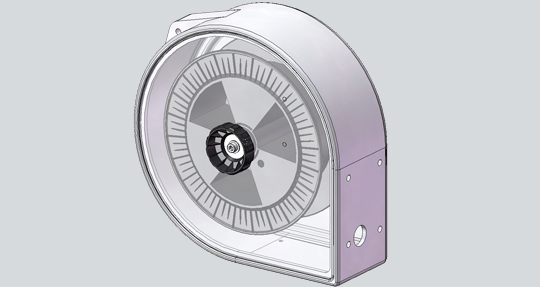

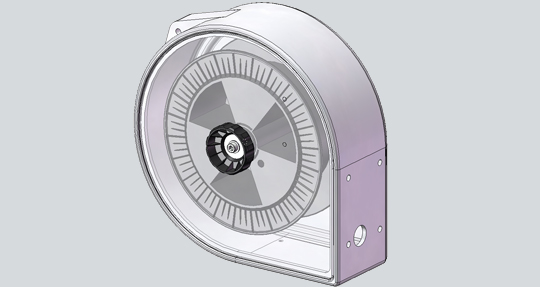

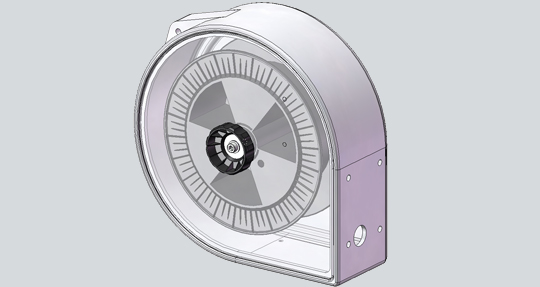

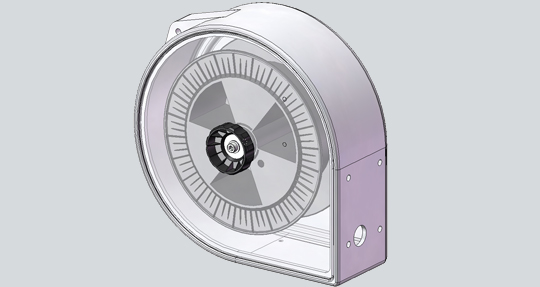

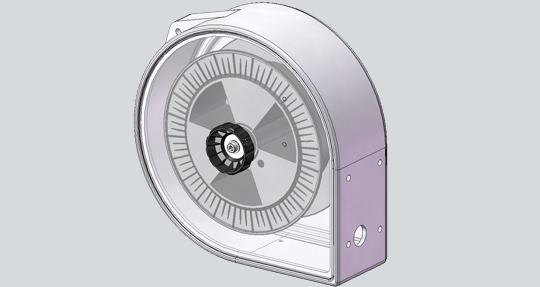

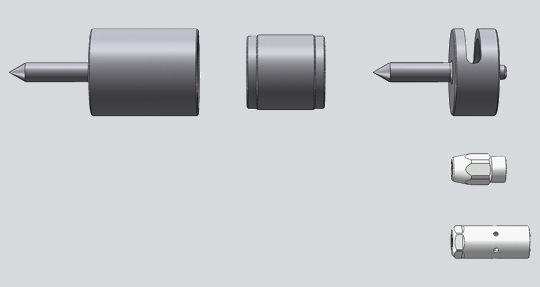

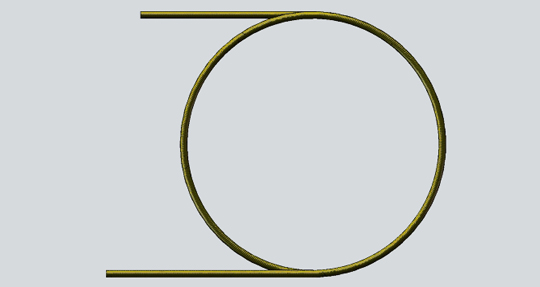

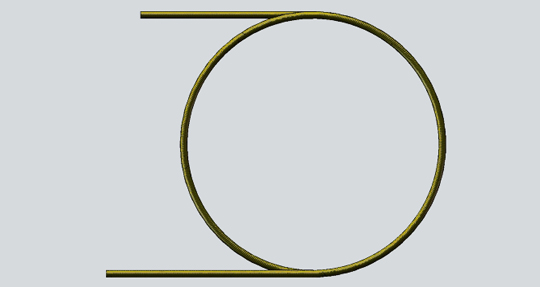

Unique cooling

The gas circulates within a cooling spindle and flows spirally along the inner tube to the contact tip. This enlarges the cooling surface significantly.

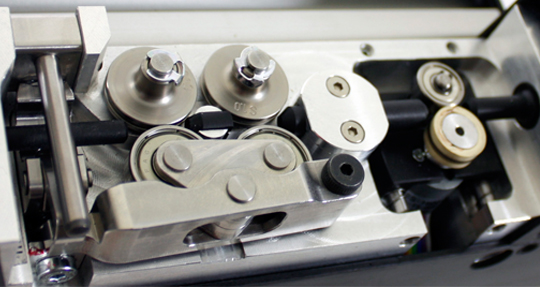

Intelligent material selection

Stainless steel is used as the base material; it is characterized by a high level of heat resistance, which brings reliable stiffness with it. Thanks to the optimized heat exchange zones, high temperatures can be dissipated effectively.

Formidable strength of shape

The support sleeve stores the heat and keeps it away from the inner tube. Thus the torch neck stays dimensionally stable.

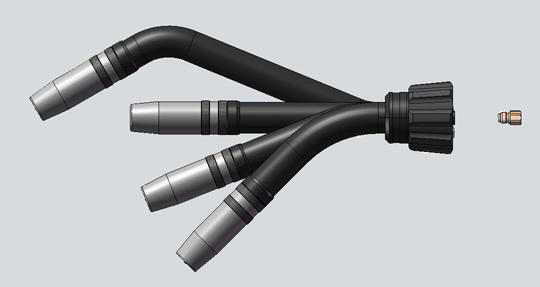

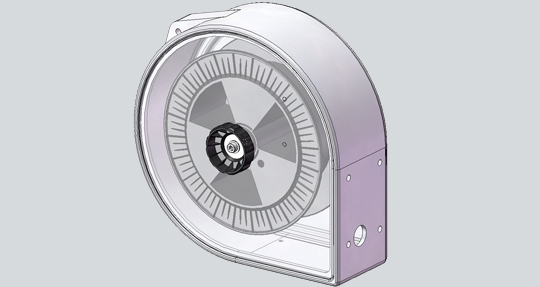

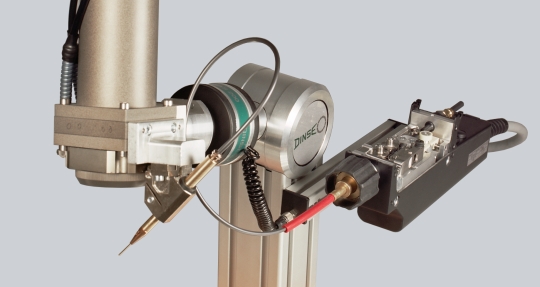

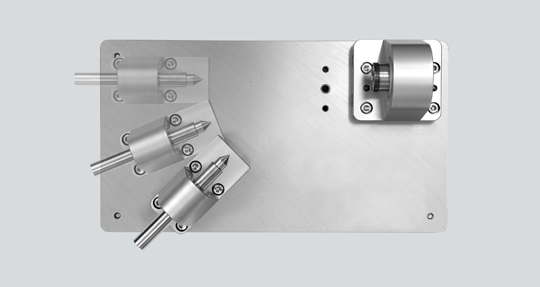

Convincing diversity

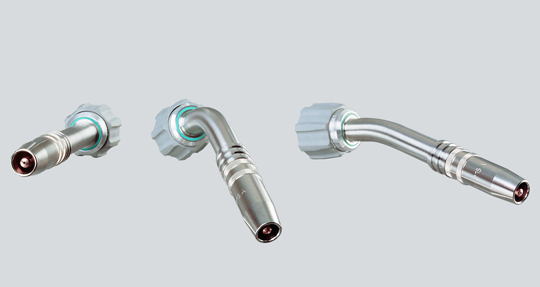

The series DIX MET 32xx, DIX MET 37xx and DIX MET 39xx offer the right geometry for any welding task. The angles are 0°, 22°, 45°.