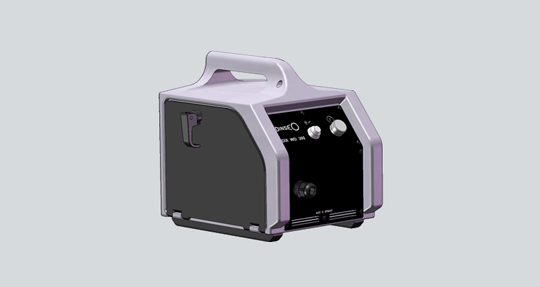

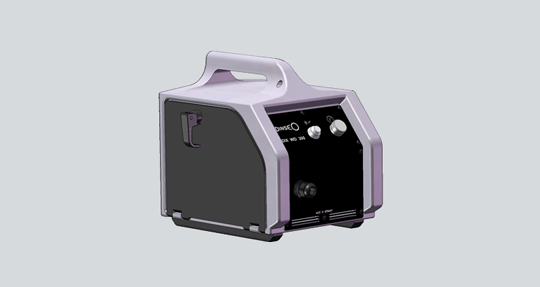

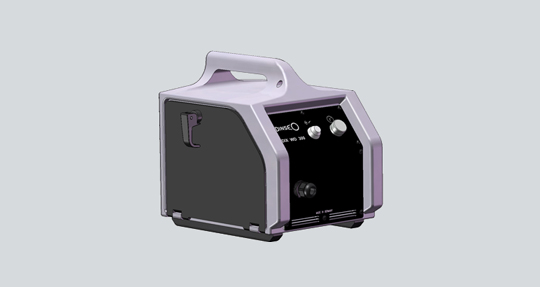

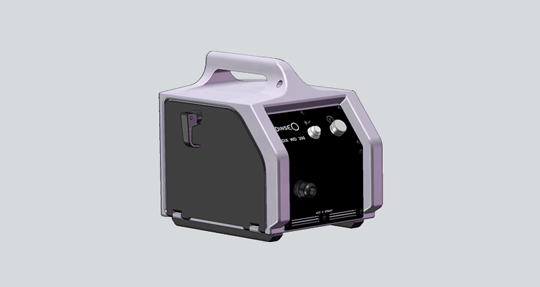

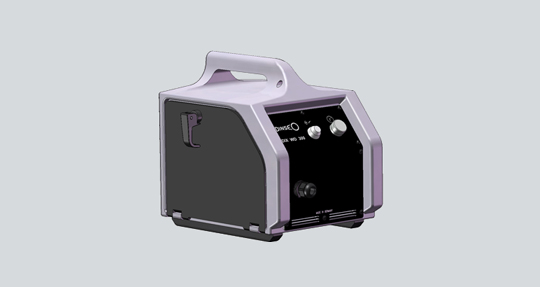

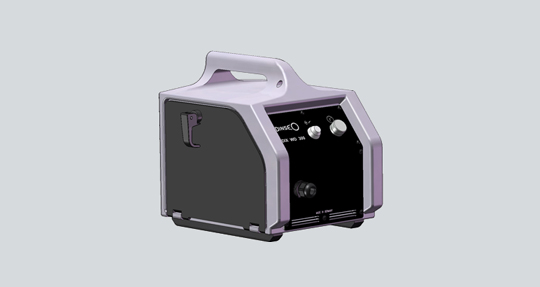

METZ 600-xx WB

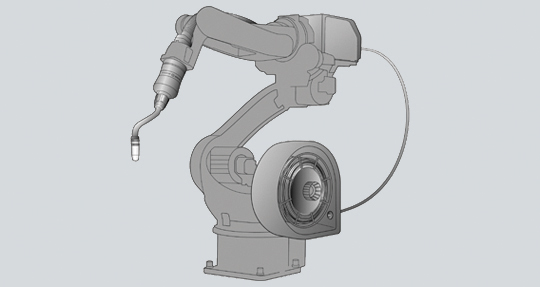

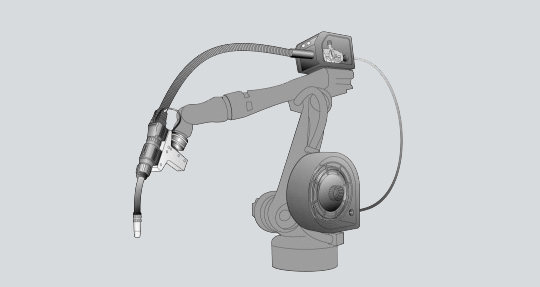

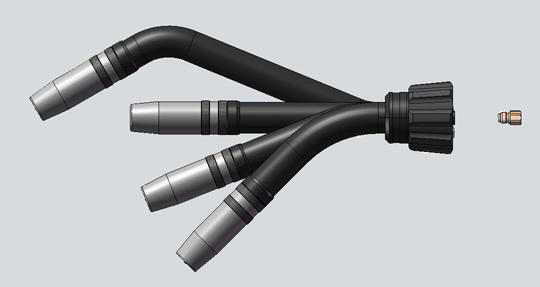

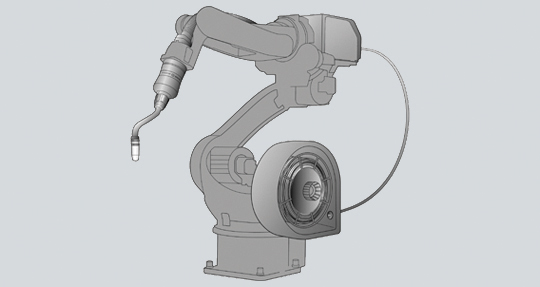

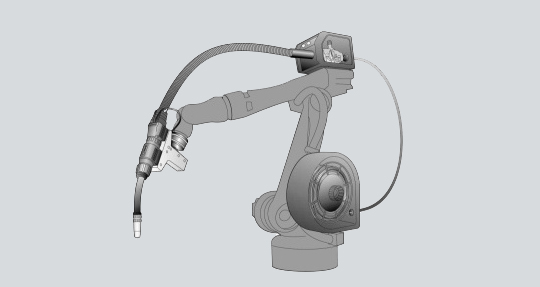

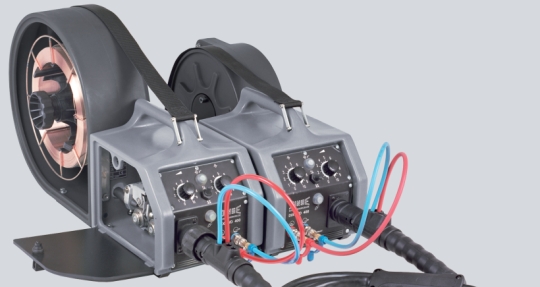

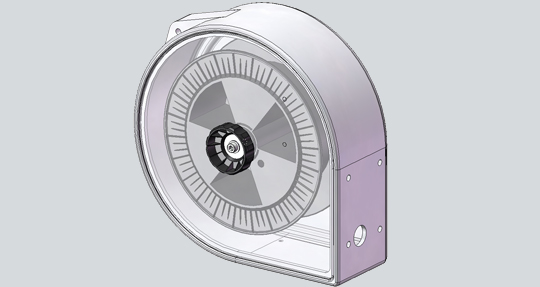

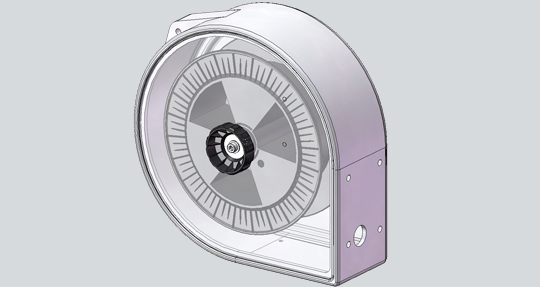

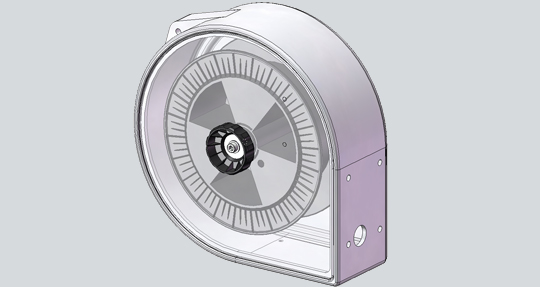

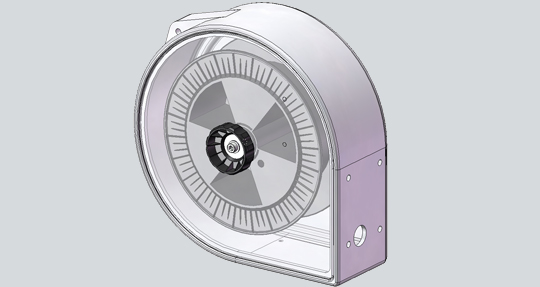

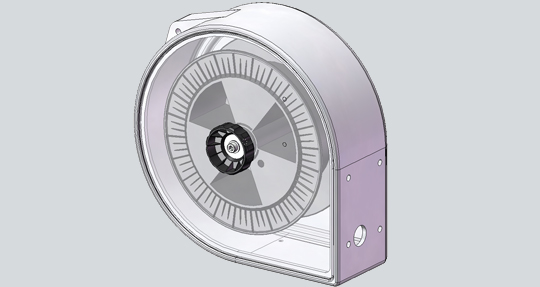

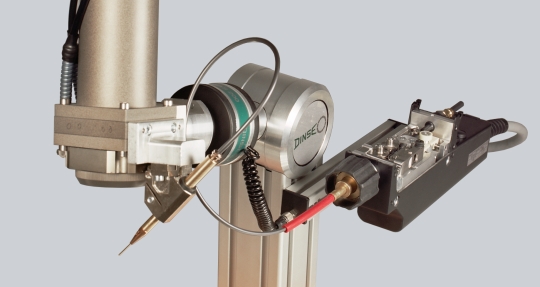

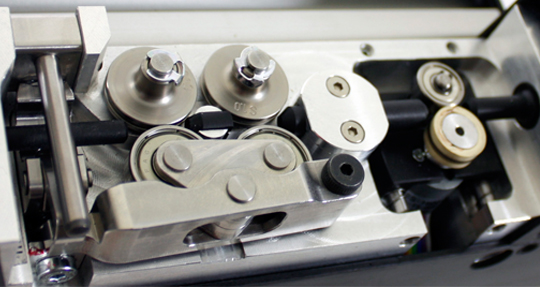

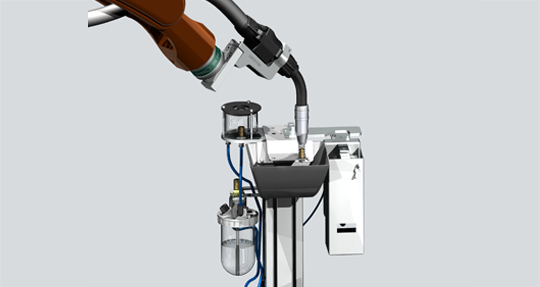

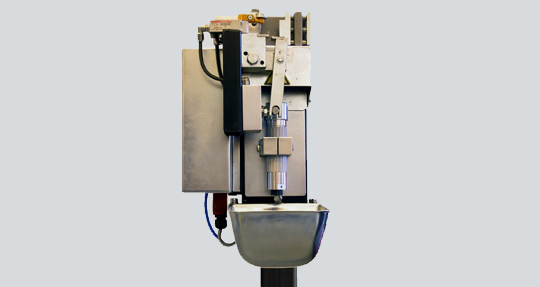

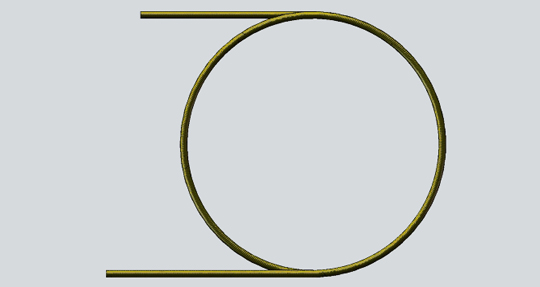

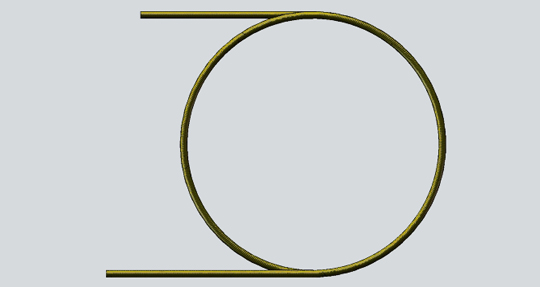

All individual components are accurately matched and can be replaced in no time at all. Durable insulation and a revolving cover hose on both sides help to ensure stable, flexible handling and reduce the load on the set. In addition to recording the various welding parameters, there are some essential mechanical features involved in controlling the transport of the welding wire. A fundamental element in this connection is the integrated wire brake. Thanks to freely programmable brake cycles, the wire brake grips the wire firmly – and always in exactly the same position. This allows the position of the weld seam to be set securely. The wire brake ensures that the the stick-out of the welding wire remains absolutely constant. A stable tool centre point is thus guaranteed throughout the entire measuring process.

Vorteile

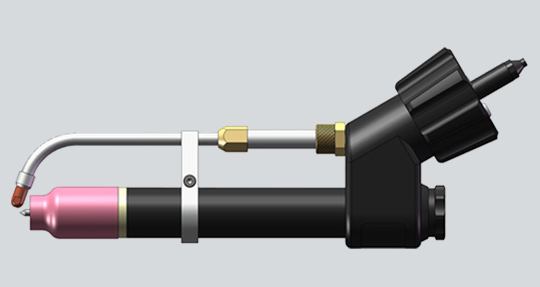

- No gas losses, due to separate shielding gas guide

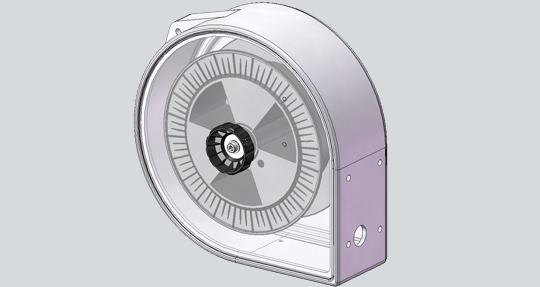

- integrated exhaust technology

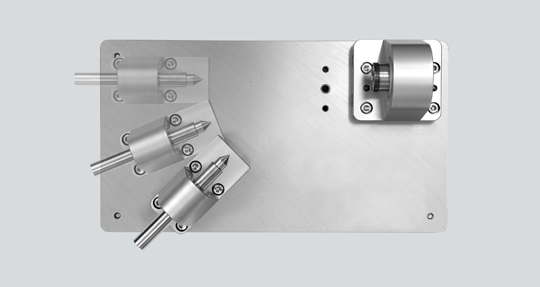

- TCP through fixed bracket or rocker

- Position reproducible through testing and setting device

- Precise safety shut-off

- Tool changer with storage station

- Precise wire feed by powerful Wire feed modules

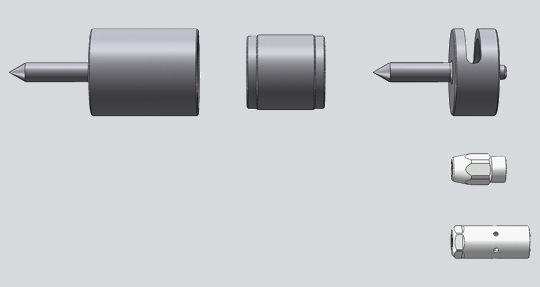

- Precise control of the welding wire advancement

- through freely progammable brake cycles, the wire brake grips the wire firmly

- Precise calculation of the welding seam position

- Simple changeover for all applications with tactile sensor

Technische Daten

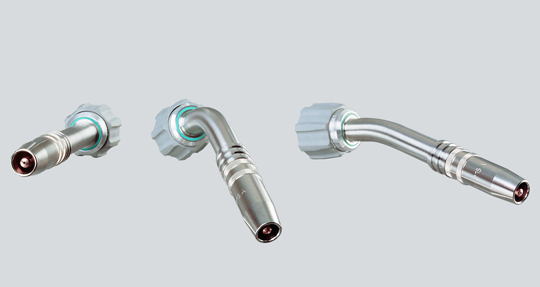

| Connection | Euro; Dinse; Power-Pin |

| Cooling | liquidcooled |

| Welding Process | GMWA; GMWA |

Manual